- Home

- E61 Group Head

- Flow devices

- Vibiemme Domobar group head Flow control device

Vibiemme Domobar group head Flow control device

160,00 €

i

i i

i i

i i

i i

i i

i i

i- Reviews

- Questions

Thank you for submitting a review!

Your input is very much appreciated. Share it with your friends so they can enjoy it too!

Buen servicio entrega rapide, aún sin probar

Group head pressure controller

Fantastic device. Provides everything I hoped for and means I don’t have to buy a lever machine. Delivery to the other side of the world in 3 days. Unbelievable

Perfect

Perfect place to buy parts for your machines, will definitely be buying more from here, great communication too answered within an few minutes on ever question.

Vibiemme Domobar group head Flow control device

Well designed & manufactured, works as advertised and expected. Recommended!

Fantastic Flow Control The opportunity for better extractions

I am happy with the purchase of the Flow Control for my VIBIEMME Domobar Super PID and other accessories. I am happy as I had the experience of Coffee Sensor where the communication was excellent, the delivery was SUPER FAST and the after series services are RARE to find. Tudor is a kind , honest gentleman willing to help his customers who ask for advices , technical questions and anything else that is useful for their coffee passion. Tudor is a coffee expert and perfectionist not only to coffee world but also to human relationships. I wanted to thank him.

Description

Characteristics

Description

Vibiemme Domobar group head Flow control device is designed in collaboration with my dear friend John M. Hauck and is the result of my company expansion process, offering flow control devices not just for the common design E61 group, but also for the more special VBM Domobar machine.

As far as i know, this is the FIRST flow control device made for this type of group head.

Available custom wood handles are (purchased separately, since we offer one plastic handle standard for each FCD kit):

CUSTOM MADE WALNUT HANDLE.

CUSTOM MADE OLIVE HANDLE.

Vibiemme Domobar group head Flow control device is designed and tested on my personal Vibiemme Domobar Super 2B machine.

KIT CONTAINS:

1. Two type of flow control device handles, one offering a fix position of the plastic handle and one offering the ability to flip it at 180 degrees. Both type of chromed brass handles are delivered with one POM handle that matches the OEM design of the other handles usually found on VBM machines;

2. New upper GH nut (polished stainless);

3. New stainless steel needle valve;

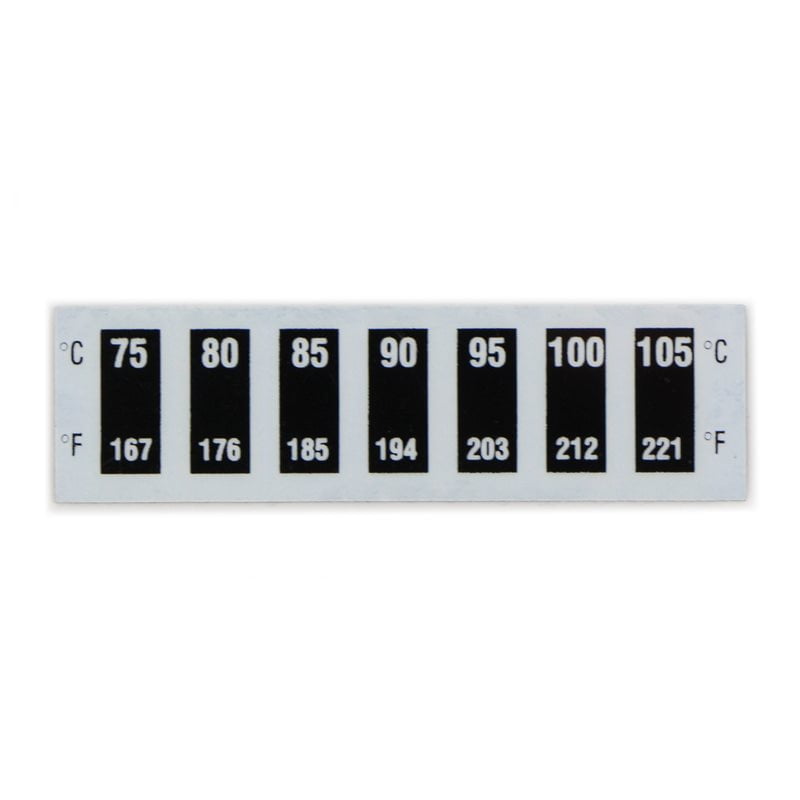

4. 16 bar pressure gauge with white mask (stem is custom made to fit the special GH type);

5. New brass screw that replaces the OEM screw from under the nut;

6. New screen filter that sits around the new brass screw, inside the GH and right under the nut;

7. New Teflon washer to be used under the new nut.

Vibiemme Domobar group head Flow control device allows the user to vary the amount of water flowing through the GH, due to its special needle valve from inside.

Different flow rates allow for lengthy pre-infusion for even more saturation and extraction of your espresso drinks.

Due to the modification of flow, the result is actually a change in pressure.

All changes are directly shown on the included pressure gauge ( branded with Coffee Sensor ) which needs to be attached on the front of the group.

The presure gauge has a direct M6 thread on the back, so the installation is pretty simple and straight forward. Use a little Teflon tape to install it.

TIPS AND TRICKS AND GENERAL INFO ABOUT USAGE:

What do you gain using a Flow Device?

- You can have a long pre infusion, meaning even minutes if you want to;

- Control your flow, considering what coffee you use or roast style’

- You can now hit a dark roast with full power or have a gentle pre infusion for the lighter roasts;

- Lever machine extraction style, simply because you can now control the pull pressure;

- You can imagine that now, you can extract a coarser coffee, just like filter type.

How to use the flow correctly and some SAFETY NOTES (PAY ATTENTION)

- ALWAYS WORK DURING INSTALLATION OR DISMANTLE PROCESSES WITH THE MACHINE COOLED DOWN;

- Set the pump pressure to correct working pressure, between the usual 9-10 bar. Some put it in 9.5 bar. It’s your call;

- Check the OEM flow rates of your coffee machine, BEFORE INSTALLING THE FLOW DEVICE. It’s best to know the OEM starting point. This means to check in 10 or 20 seconds for example, how much water the machine gives you per second, without our product installed; the flow can be measure in ml/sec or grams/sec;

- Install the group head manometer BY HAND / USING ONLY THE FINGERS AND ALWAYS TIGHTEN ONLY TOUCHING THE BODY OF THE GAUGE (BACK PLATE) AND NOT THE FACE / MASK / GLASS.

Use a little Teflon tape (white tape provided inside the box) on the gauge’s thread for sealing purposes. Grab the manometer’s body (NOT FACE) with your hand / fingers and make a few turns with the tape (ALWAYS CLOCKWISE), to seal the gauge properly. DON’T USE A KEY OR WRENCH WHEN TIGHTENING. This could damage the thread on the manometer / thread inside your GH. THIS IS A FINGER TIGHT PROCEDURE. Insert gauge inside the GH until you feel it touches the end of the hole. Just make sure the readings are positioned horizontally and that’s it. Test with a blind basket for any water leaks. FOR YOUR SAFETY, MAKE ANY TESTS NOT SITTING IN FRONT AND NOT LOOKING DIRECTLY AT THE FLOW CONTROL DEVICE OR AT THE GAUGE !!! Just stay close and pay attention to any air pressure / water leaks. If there are any present, close even better the FCD or turn the gauge a little bit more clockwise. If there are not any leaks present, you are good to go. - Install the flow device and check the new flow rates it gives you at different points (angles or clock digits). You can install any handle and set the COMPLETE CLOSED / SHUT OFF point at any desired degree / hour position, like 12 o’clock, 9, 6 or 3; We are going here counter clockwise;

- Check the flow output by turning the flow like we said, counter clockwise; you should see on an ECM machine for example, if the SHUT OFF COMPLETELY point is set at 12 o’clock, that at 9 o’clock, you could have a 2-3 ml per second flow, at 6 o’clock a 4 – 6 per second, and at 12 again, over 7 ml per second and so on;

- Always use a cup with ml on it or a scale to determine best water output as stated above;

- Split the results in 10 or 20 (the number of seconds you left the water run with the pump ON), to determine the correct water output your machine gives PER SECOND; this is how you determine grams per second or ml per second flow rate using the Flow Device;

- Understand that the FCD touches the group directly. This means it WILL GET HOT DURING OPERATION. Pay attention when turning the FCD’s handle, NOT TO TOUCH ANY METAL PARTS. The handle itself is made from a special heat resistant plastic, so no harm there;

- Decide if you wanna extract coffee using the flow or pressure parameters (or both). These are different aspects during extraction. Explained as simple as possible, if you want to handle / influence the extraction considering flow, you need to know your flow points and the water output at certain angles;

- If you want to use pressure as no. 1 parameter, just watch the group head manometer / gauge readings and use the Coffee Sensor Flow Control Device for E61 group heads to obtain a certain pressure at a certain moment. But we recommend using flow, because pressure rises and lowers fast (the gauge readings fluctuate), while flow is usually constant, after determining the water outputs;

- The FCD work mode is influenced by a lot of factors , some of them in a bad way, like warned out gaskets, springs, SCALE BUILD UP INSIDE YPUR GH. Pay attention to these details, if you wish to obtain best results with out product ! A bad seal somewhere could mean that the FCD just cannot fully operate and give you normal low or high pressure during operation.

Quick QA:

- Is my pump affected by the Coffee Sensor FCD? No it’s not, because simply put, the pressure inside your machine up until the FCD working point, is the standard setup up 9-10 bar. The pressure lowers or rises only after the FCD working point. So all the internals always work at the standard parameters and not the modified ones.

- Is my heat up time affected since the FCD usually stays in CLOSED position? No, because the closed part or zone is just above the area where the water circulates slowly inside the GH, with the help of IN and OUT pipes.

- Will my pump be affected on the long therm? No it will not be or correctly put, a normal pump with no factory problems, will handle the FCD a long time. The low pressure given by the FCD usage lasts for seconds. The pump is not engaged with low working pressure for days or years. An extraction usually lasts tenths of seconds and all day long 🙂

- What handle should i use? Any you like, but certain coffee machines have a lower positioned group head, so the standard handle could hit the machine’s body. In that case, it’s best to use our flip handle, to avoid the chrome plate from behind the group head.

- What are the spare gaskets and the food safe grease for? They are for lubricating from time to time the internals of the FCD. Also, spare gaskets are for servicing purposes.

- Do i have some warranty? Yes you do. ALL METAL PARTS MADE BY COFFEE SENSOR HAVE LIFETIME WARRANTY. Gaskets are not included in this statement.

- Do all machines have same water output? Of course not. Each and every machine is different, rotary pumps work in one one, vibe pumps in other way and so on. The idea with the FCD is to give you the ability to modify the standard flow, but how much, depends on each and every E61 coffee machine.

- What models are compatible with the Coffee Sensor FCD? All that have standard not modified E61 internals.

Characteristics

| Weight | 232 g |

|---|---|

| Dimensions | 6 × 3,7 × 0,4 cm |

| PRESSURE GAUGE COLOUR | BLACK, WHITE |