- Home

- BLACK FRIDAY 2024 (ENDED)

- La Pavoni Sales

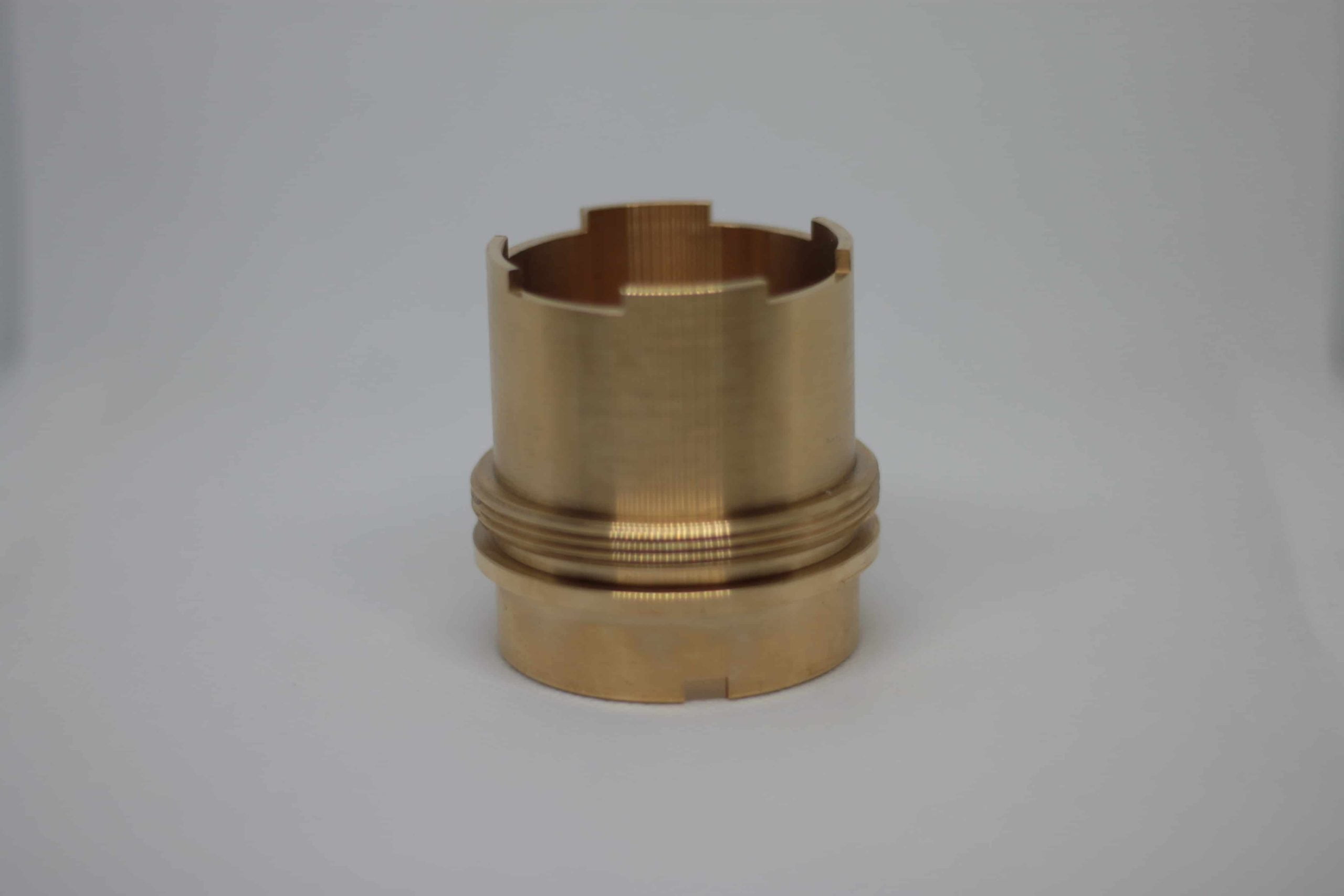

- La Pavoni Custom Made Brass Sleeve Jacket

La Pavoni Custom Made Brass Sleeve Jacket

65,00 €

i

i i

i i

i- Reviews

- Questions

Thank you for submitting a review!

Your input is very much appreciated. Share it with your friends so they can enjoy it too!

A perfect upgrade!

A well engineered part reflecting Coffee Sensor's passion for La Pavoni machines. A first class service, Thank you!

Better than plastic!

Using it for 3 years now. De- and remounted it for cleaning with the custom-made tool, which I bought with the sleeve. Works like a charm!

Great product

Such a well built piece for my Europiccolla.

Best upgrade possible!

My europiccola millennium had the usual factory-installed plastic sleeve, but within six months of use the lever was getting jittery, and when I took the group head apart found that it had in fact become deformed - presumably through high temperatures and high pressure. I bought a brass sleeve from Coffee Sensor, installed it, and the machine is now working like a dream. It pulls more smoothly than ever, and the thermal conductivity of the brass allows the group head to heat up more quickly but without overheating. I'm pulling the best shots imaginable! Coffee sensor was brilliant, and despite the usual potential import issues/delays because of Brexit, sent the part so that it arrived within a couple of days. Top rating!

Great purchase

Very good quality

Description

Characteristics

Description

La Pavoni Custom Made Brass Sleeve Jacket is specially created for the NEW GEN / Post Mill / Big GH La Pavoni EP / Pro coffee machines.

Our official installation tutorial is finally here:

The product is offered both BRASS – CLICK TO VIEW. and STAINLESS STEEL- CLICK TO VIEW..

The sleeves have been tested by us, both the brass or stainless steel version, with very little differences between the two materials, regarding working temperature.

We did notice that the stainless steel does not incorporate so much heat as brass does but offers a little bit more stable working temperatures.

We offer both materials just because usually there is also a personal taste involving this purchase.

When we created a poll, some wanted brass and some wanted stainless steel. So there you have it !

It replaces the old and problematic plastic sleeves from inside your coffee machine.

Coffee Sensor has the Motto “no more plastic inside La Pavoni’s”. That’s why I created this sleeve but also the metallic boiler water pipe connector and so on.

With the help of a very special group of coffee enthusiastic people, we researched and still do, LP’s problems and try to find the best solutions.

So we came up with this new and improved product for your La Pavoni.

La Pavoni Custom Made Stainless Steel Sleeve Jacket does not solve the overheating problem that can occur inside the Post Millenium coffee machines, but rather offers a much better temp surfing and recovery time.

The water flows and gets inside the coffee puck with the help of our single hole system. The sleeves are drilled once, not two or three times like other manufacturers thought about.

Even if we tried and made here the hole to sit directly the opposite way of the water inlet hole and thus, offer a full road cycle for the water from the boiler to the puck, from my personal experience, the inside thread of the group heads IS ALWAYS DIFFERENT.

It means that regardless how we create the sleeve’s hole here, it will always face differently inside another group head.

Just screw the sleeve all the way to the end and use it happily ever after.

We do not offer a gasket, but you can purchase a new one right HERE – CLICK TO VIEW.

We strongly suggest you replace the old o ring with this occasion.

Also if you need a sleeve removal tool, we made one specially for this operation, and you can purchase that right HERE – CLICK TO VIEW.

SPECIAL NOTES FROM US:

The sleeve body is made using a modern CNC machine.

After this step, each and every sleeve is hand made to perfection.

We need to make a sign for the hole, drill it of course, sand paper the inside of the sleeve to get the waist out so that it will not interfere with the piston gaskets and so on.

Also, sometimes we need to make some parts / zones wider or narrower, polish and such.

This is why you will see on the sleeves some small signs of handcraft processes.

The metal sleeves will never get inside the group head as easy as a plastic part.

It’s best to LUBRICATE THE SLEEVE GASKET ON THE OUTSIDE before inserting it inside the GH.

Also, make sure the angle of the metal sleeve’s thread and the angle of the GH’s inside thread are PERFECTLY aligned, so that there will be no thread modified / tear apart when screwing the sleeve.

We recommend using our tool for the entire operation, simply because its much easier to remove the old sleeve and get the new metal one inside, without much trouble.

Pay attention to the alignment. It’s very important.

If you feel you cannot control the entire removal and insertion processes, please apply for professional services.

Characteristics

| Weight | 175 g |

|---|